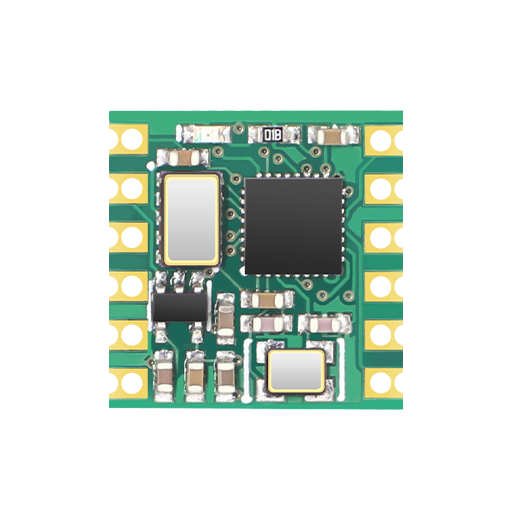

Q: Can MSY self-organizing network equipment maintain normal operation in an extremely cold environment of -40℃ at an altitude of 5,000 meters? How to ensure RF stability?

A: Through the full temperature range adaptive system (-55℃~85℃ verification), the MEMS RF compensation algorithm is used, and the power fluctuation is <1dB in a low-pressure environment of 5,000 meters. With the vacuum coating protective layer, it ensures 72 hours of continuous operation in an extremely cold environment at high altitude (has been tested on the Qinghai-Tibet Plateau).